Choosing the best threading method

[ Time:2021-02-23 Click:584 ]

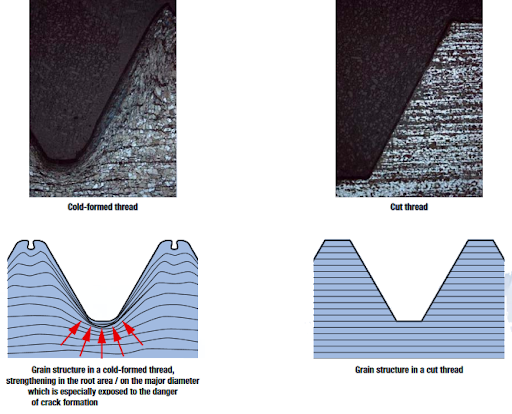

Cut thread VS Rolled thread

Is it necessary to specify the machining method?

Are the differences in the end product significant enough that a designer should give additional consideration to this question? In some instances, yes.

Following are some main considerations to help determine if rolling or cutting is the right machining method for a fastener or threaded part.

1. Type of material

The rule of thumb is that materials thar are easy to roll are difficult to cut and vice versa.

This is true in the majority of instances. The determining factor is plasticity. Materials that have food plasticity are better suited for rolling. These are generally materials with an elongation factor of 12% or more.

Metals that are suitable for rolling are typically difficult to cut and have a higher degree to plasticity.

2. Reliability

Rolling threads have an increased ability to resist fatigue. Applications with threaded parts and fasteners that are expected to operate reliability in high -pressure environments will benefit from rolled threads vs machined.

The rolling process leaves the read with smooth burnished roots and flank, free from tears or chatter which are often starting points for fatigue-related failures.

3. Required part strength

As with reliability, rolled threads provide increased part strength. Parts that are rolled have a root hardness that can be as much as 20% to 30% greater than those that are cut.

Tensile strength can be as much as 10% greater. Shear strength is also increased because shear failures must occur across the great rather than with the grain.

4. Chipless operation

Rolling creates burr free knurls and eliminates chatter. A rolled thread is less likely to have any debris that flakes off the component and enters the operating environment. This is a major consideration for applications that must operate reliably and cannot afford to have debris fouling the operating environment.

5. Quantity

Jobs with large production volumes may lend themselves to rolling, if other qualities to do not dictate that cutting be used instead. Production speeds in the rolling machining process are much faster than those of cutting. Rolling uses less material at a faster rate of production with fewer defects.

6. Required tolerances

For parts thar require high degrees of toerance and limited variation from part to part, rolling offers significant advantages over cutting. The nature of the rolling process ensures that the last part produced will be as perfect and precise as the first. Applications requiring high degrees of tolerance and part uniformity in large production volumes are better suited for rolling than cutting.

7. Required surface finish

Applications that require fasteners with a superior surface finish will want to select rolling over cutting. Rolled threads are burnished and work hardened by the rolling process and as a result have abetter apperance.

8. Type of thread

For applications that require very deep or coarse threads or those that require multiple threads, cutting should be the primary consideration. Rolling does not allow for the angle to be great enough to accommodate most types of multiple threads or very deep/non-precise threads.

9. Type of application

The application in which the fastener or threaded part will be used may also determine if rolling or cutting is employed. Some industries, such as aircraft components or nuclear components require rolling. Others, such as medical devices, dental devices and valves would significantly benefit from rolling.