NDT Inspection on High Strength Steel Bolt

[ Time:2020-12-11 Click:725 ]

Magnetic particle inspection, also called MPI , or MT is a non-destructive test(NDT) process for detecting surface and shallow subsurface discontinuities in our heat treatment steel round bar materials. In order to improve our produce quantity, our wind turbine foundation system anchor bolt, roof support system anchor bolt, round bar, high duty stud bolts and many other materials need this test as per clients demands.

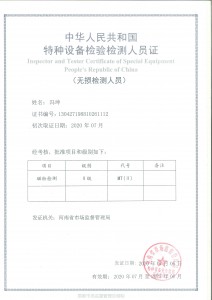

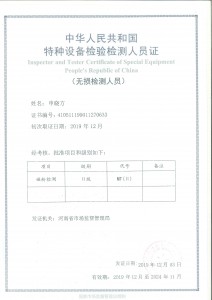

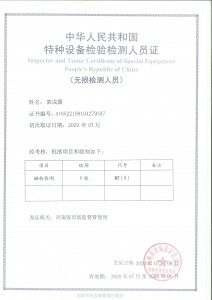

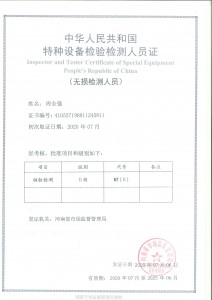

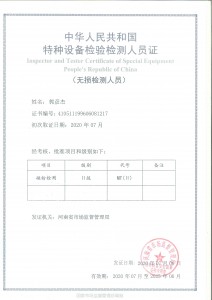

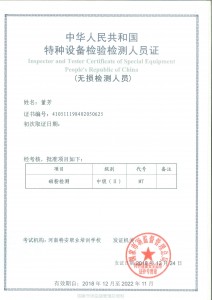

Inspection workers qualification

Detective workers attend training and tests from national quality supervision and certified.

Inspection workers trained and 100% certified.

INSPECTOR AND TESTER CERTIFICATE OF SPECIAL EQUIPMENT PEOPLE'S REPUBLIC OF CHINA

Anyang Longteng NDT operators have documented training and are certified according to standard NBT 47013, inspectors are certified level II . Equivelent to NS-En ISO 9712 standard, level II

According to customers' requirements, Anyang Longteng will submit NDT testing and acceptance criteria to be approved by the client.

Magnetic Test Instrument and Methods:

According to GB/T 4730.4-2005 <Nondestructive Testing of Pressure Equipments-Part $: Magnetic Particle Testing>,also referring to ASME SE-709<High pressure boiler and vessel general rules,standard gudide for magnetic particle examination> V, GB/T 4730.4-2005, ASTM and JIS G0565 ,EN1290:1998 general rules.

Non-contact fluorescent magnetic powder flaw detector, combining of coils and yoke for flaw detection, the magnetic suspension concentration is checked by every shift then de-magnize.

100% test piece by piece.