M48 Gr 10.9 bolts 700KN for pretension turbular tower foundation

[ Time:2019-06-17 Click:2012 ]

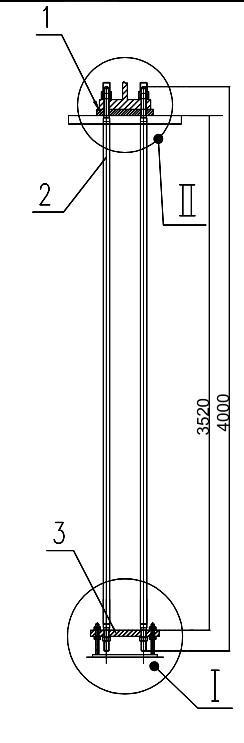

An Anchor cage is composed by anchor bolts, 2 anchor plates(templates)-upper template(temporary template, upper anchor bolt), lower template(lower anchor bolt), Steel Nuts, seal nut(nylon nut), Washers(gaskets), adjusting feet assemblies, splice plates(connecting plates), PVC tubes, corrosion protecting grease, fabric,HDPE bolt caps(bolt hat) etc

STANDARDS: GB/T 3098.1 ISO 898-1 OR AS CUSTOMER'S REQUIREMENTS

Anchor bolts are the most important part in this assemblies in WTGS(wind turbine generator system) since this part will bear the pre-stress, pre-tensioning forces, and take responsibility for the stability of the whole turbine or tower. Our manufacturer have the most advanced facility of heat-treatment of steel round bars, which means the pre-stress bearing capacity, tensile strength, yield strength abilities are much higher than the international standards. That is the reason why many world-wide companies choose us.

Anyang Longteng Heat Treatment Material Co.,Ltd is a threaded bolt manufacturer. We provide heat treatment services, cold thread, random length, bolt assemblies supply. Contact infor@aylttg.com for a free quote.

We produce 42CrMoA steel bolts for wind turbine foundation anchor cages. 42CrMoA is a high level alloy steel grade of GB standard, which equal to A193 B7. This replacement has been proven by many overseas clients. Contact us, we will send you original mill test certificate of 42CrMoA.

Rod Properties:

Property Class: 8.8 9.8 10.9 12.9

Diameter : M16 to M56

Tensile Strength : 860 MPa, 900MPa, 1040Mpa, 1220Mpa , or according to client's requirements.

Yield strength : 600 MPa, 650 MPa, 830 MPa, 970 MPa, or according to client's requirements.

-40 ℃ Impact energy: higher than 27J

Rockwell Hardness HRC: 23 to 44, or according to client's requirements.

FOR YOUR EYES ONLY

Production Line

Quality Control

Certificates

Achieving the ISO 9001:2008 Certification is just one example of our Products’ dedication to quality and continuous improvement. Each employee is responsible for understanding company expectations and adhering to the procedures of our Quality Management System.

Our Products ensures customers receive the material ordered with accurate supporting paperwork. Customers can count on proper documentation, on-time performance and effective follow-up.

Guarantee

We will continually improves and expands the quantity and quality of our product which exactly meet customers need. We do whatever it takes to make our clients happy.

We will develop long-term commercial and technical partnerships with customers. And we are committed to continual quality improvement of all internal processes. The success of our quality program is affirmed by our strong customer retention rate.

Contact infor@aylttg.com for a free quote, we will reply within one working day.